Turning designers dreams into reality.

Conceptualization and Design

The transformation of your designer’s dream into a working reality takes a very special combination of talents. While modern technology and high-tech machining play key roles in the process, the human element of skilled engineers and craftsmen, including moldmakers, technicians and machinists, also contribute to the master plan. Since 1952, L&Z Tool and Engineering has demonstrated the ability to make ideas successfully materialize into the market place.

After receiving your plans in virtually any data format, L&Z’s team of highly experienced engineers carefully reviews every aspect of the project, working concurrently on each required step – from design to delivery. L&Z offers customized design solutions in-house or we can link up electronically via modem or EDI to your CAD database. After thorough review and project approval, the actual manufacturing process begins. Using our SOLID MODELING capability, L&Z performs the following:

- A working prototype is created using CAD technology and/or 3D printing.

- The designer electronically creates an exact engineering model of the parts involved in the project in 3-D employing various colors, textures and environments.

- Where necessary, accurate prototypes are created using advanced rapid prototype modeling techniques such as RP, STL, SLA [Stereolithography modeling techniques] or Laser Based Metal Deposition [SLS] to anticipate and identify potential appearance or structural problems.

- Using the latest 3-D design software, a mold design is created and reviewed with you, the customer. With our cutting edge technology we are able to meet all of your requirements for single or multiple molds, in virtually any size or shape.

Planning, Scheduling and Production

L&Z is proud to be an AMERICAN company producing every plastic mold, die, and tool on-site at our facility in Watchung, New Jersey. As an ISO-9001:2015 registered company, we use the finest American made materials which conform to the strictest international quality standards.

The planning stage blends L&Z’s traditional master artistry with modern technology. Based on your project’s specifications we can accomplish the following:

- Generate a physical working prototype via the CAD system, CNC machine or a handmade model constructed by an L&Z craftsman.

- A flow analysis and/or FEA can be performed by the L&Z team to predetermine the most efficient gating and to determine the feasibility and workability of your design.

- Once you are completely satisfied with the outcome, the actual design detailing and manufacturing begin. The finest materials are ordered and a production schedule is developed.

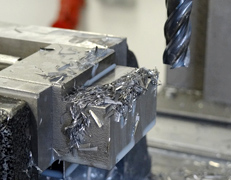

- A combination of CNC and EDM processes are used to create geometries with any degree of complexity.

- L&Z technology and equipment is constantly being upgraded. We pride ourselves on our state-of-the-art facility featuring 4 and 5 axis high speed machining, wire EDM and EDM work cell.

The Finished Product

The computers and machinery play an integral part in the completion of your project. This technology, however, can never take the place of the artistry skills that L&Z’s experienced craftsmen possess. The master craftsmen lend their moldmaking skills through intricate precision finishing and polishing touches with hand tools. The majority of L&Z’s staff has over twenty years experience in the fine art of moldmaking and takes great pride in every tool that is produced. Whether your project is large or small, simple or complex, the molds are carefully assembled and tested for precise fit. L&Z guarantees that each part will meet exact specifications and be delivered according to schedule.

L&Z's Value Added Service

As a value added service, L&Z can provide engineering changes, repairs, modifications or refurbishment of existing products according to exacting specifications. L&Z is also one of the only mold builders to offer hand-engraving capability.